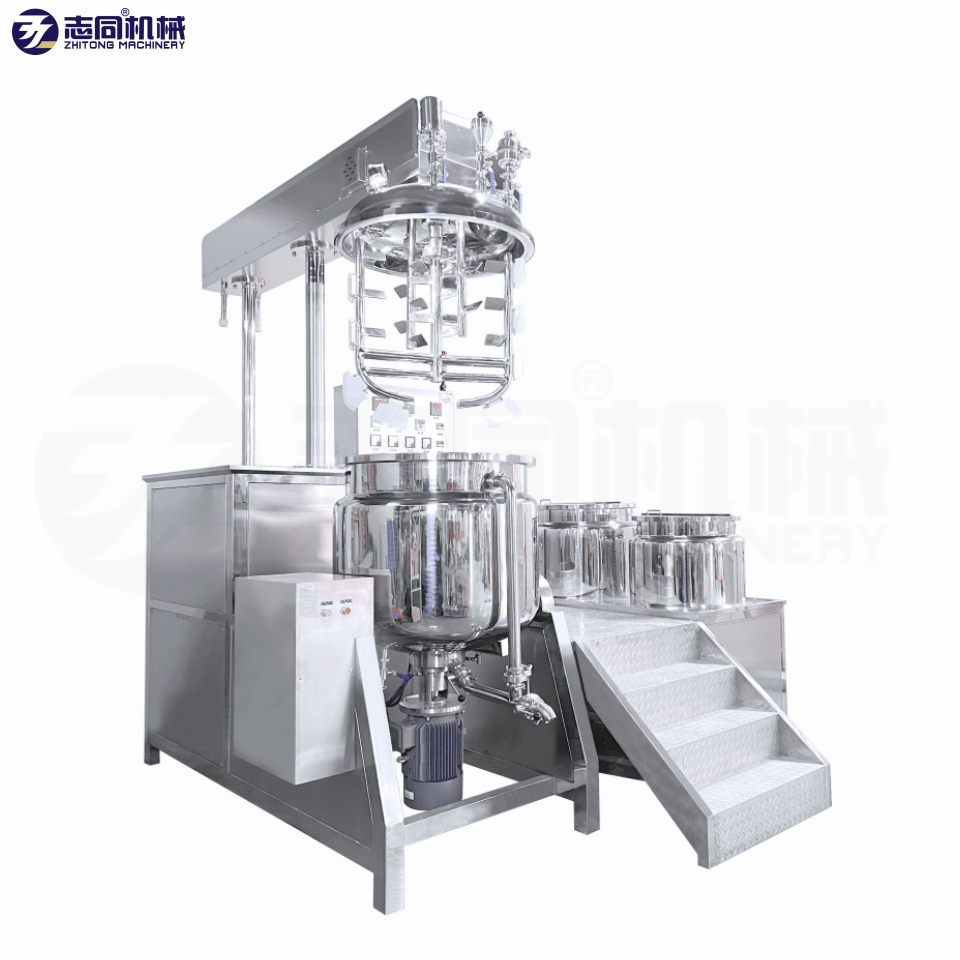

Product Description

1. Working capacity from 10L to 50L;

2.Suitable for cream and emulsion of 30,000~100,000cps viscosity;

3.Variable speed for homogenizer and agitator;

4.Make the material can be fully mixed, stirred and emulsified

5. All contact parts are made of SS316L and mirror polished for product quality;

6. Make the material can be fully mixed, stirred and emulsified;

7. Spray ball is equipped to connect to customer’s CIP system for self-clean process.

8. The blending system of the vacuum emulsifying mixing equipment adopts advanced triple blending and frequency conversion speed adjustment, so ads to satisfy production of different technology requirement;

9. Vacuum system to take out the air bubbles during mixing and to transfer the ingredients;

10. Oil hydraulic lifting system for easy cleaning and maintenance;

11. Double jackets for heating and cooling for customer more optional.

12. Upgrade from laboratory level to production level.

13. Easy to clean, convenient and economical;

14. Equipped with seals suitable for medical applications.

15. Homogeneous agitator is installed at the bottom, which can give full play to the effect of homogenization in small production and very little oil.

16. Supporting stainless steel water phase dissolving pot, oil phase dissolving pot, vacuum pump, buffer tank, control electric box, etc.

17. The medium material of the water pot and oil pot is added to the main emulsification pot through the feeding method.

18. Avoid storage of materials, and to make cleaning more convenient.

19. Variable speed for homogenizer and agitator.

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (kw) |

Oil water pot power (kw) |

Hydraulic lift power (kw) |

Vacuum pump power |

Total power(kw) |

||||

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor |

Steam heating |

Electrical heating |

||||

|

RHJ-10L |

10L |

8 |

5 |

0.37 |

1.1 |

0.15 |

0.55 |

0.55 |

3 |

6 |

|

RHJ-20L |

20L |

18 |

10 |

0.55 |

1.5 |

0.15 |

0.75 |

0.75 |

3 |

6 |

|

RHJ-30L |

30L |

25 |

15 |

0.75 |

2.2 |

0.15 |

0.75 |

0.75 |

9 |

18 |

|

RHJ-50L |

50L |

40 |

25 |

0.75 |

3-7.5 |

0.75 |

1.1 |

1.5 |

13 |

30 |

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

||||||||||

Application

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam:

1. fine chemicals: plastics, fillers, adhesives, resins, silicone oil, sealants, slurry, surfactants, carbon black, colloid mill, emulsifying machine, filter defoaming agent, brightener, leather additives, coagulants, etc.

2. daily chemical industry: washing powder, concentrated washing powder, liquid detergent, all kinds of cosmetics, skin care.

Option

1. power supply: three phase : 220v 380v .415v. 50HZ 60HZ

2. Capacity : 50L up to 500L

3. Motor brand : ABB. Siemens option

4. Heating method: Electric heating and steam heating option

5. control system plc touch screen. Key bottom

6. Fixed type or Hydraulic lifting type or Pneumatic lifting

7. variety of paddle designs meet difference requirement

8. SIP is available upon request for cleaning process

Video

-

1L10L Laboratory Homogenizer Mixer Lab Vacuum E...

-

Internal and external circulation emulsifying m...

-

Stainless Steel High Shear CE Certificated Euro...

-

Fixed type vacuum homogenizer cosmetic mixer ma...

-

Fixed type vacuum homogenizer mixer machine ski...

-

Hydraulic lifting vacuum emulsifier mixing mach...