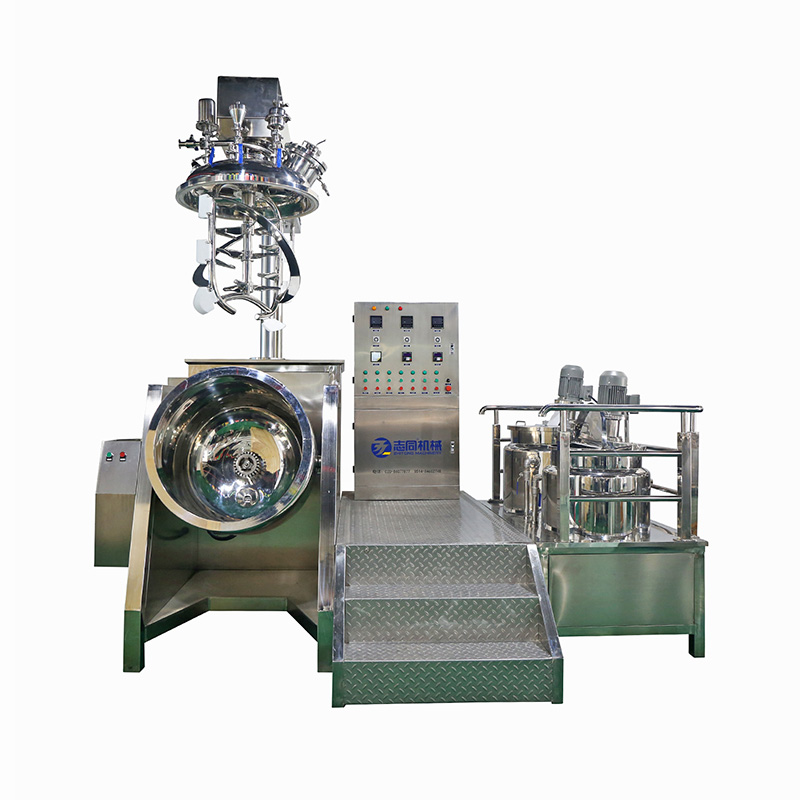

Product Description

1. Blades-mixer and homogenizer could also be operated independently.

2. Mechanical screw lifting system is very easy to start machine

3.Various high quality products can be customized according to your requirements.

4. The mixing systems include single-way mixing, double-way mixing and helical ribbon mixing.

5. Blades-mixer and homogenizer could also be operated independently.

6. Various high quality products can be customized according to your requirements.

7. Shorter batch time compared with vacuum emulsifying mixer.

8. 3600rpm high-speed homogenizer, fineness 0.2-5um.

9. Electric heating by Water or Conduction Oil Steam . electrical heating.

10. Mixing: High shearing DISPERSER plates with baffle on wall.

11. Perfect particle size of 2 micrometers and evenly distributed.

12. Push buttons control panel for easy operation;

13. Mirror polishing inside and outside reach GMP standard.

14. lifting system for easy cleaning and maintenance;

15. Contra mixing system of fixed impellers with holes and wall scraper in order to protect the product and better effective.

16. Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

17. High-speed motor, long-life design, stable operation.

18. The lid of the material pot is an automatic lifting type. The materials in the water pot and the oil pot can be directly sucked into the emulsification pot under vacuum through the conveying pipeline. The discharge method is the emulsification pot body flipping and tilting.

19. The working head is made of stainless steel, which can be reused, GMP standard.

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (kw) |

Oil water pot power (kw) |

Hydraulic lift power (kw) |

Vacuum pump power |

Total power(kw) |

||||

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor |

Steam heating |

Electrical heating |

||||

|

RHJ-10L |

10L |

8 |

5 |

0.37 |

1.1 |

0.15 |

0.55 |

0.55 |

3 |

6 |

|

RHJ-20L |

20L |

18 |

10 |

0.55 |

1.5 |

0.15 |

0.75 |

0.75 |

3 |

6 |

|

RHJ-30L |

30L |

25 |

15 |

0.75 |

2.2 |

0.15 |

0.75 |

0.75 |

9 |

18 |

|

RHJ-50L |

50L |

40 |

25 |

0.75 |

3-7.5 |

0.75 |

1.1 |

1.5 |

13 |

30 |

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

||||||||||

Application

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam:

1. fine chemicals: plastics, fillers, adhesives, resins, silicone oil, sealants, slurry, surfactants, carbon black, colloid mill, emulsifying machine, filter defoaming agent, brightener, leather additives, coagulants, etc.

2. daily chemical industry: washing powder, concentrated washing powder, liquid detergent, all kinds of cosmetics, skin care.

Option

1. power supply: three phase : 220v 380v .415v. 50HZ 60HZ

2. Capacity : 50L up to 500L

3. Motor brand : ABB. Siemens option

4. Heating method: Electric heating and steam heating option

5. control system plc touch screen. Key bottom

6. Fixed type or Hydraulic lifting type or Pneumatic lifting

7. variety of paddle designs meet difference requirement

8. SIP is available upon request for cleaning process

Video

-

hydraulic cylinder emulsion mixer machineI Cosm...

-

Combine Customize homogenizer Mixer tank indus...

-

Stainless Steel High Shear CE Certificated Euro...

-

Hydraulic lifting type vacuum emulsifier|Vacuu...

-

Internal and external circulation emulsifying m...

-

Vacuum Homogenizer Emulsifier|Cosmetic Homogeni...